I’m currently reading a book called “The Art of Noticing”, by Rob Walker, which is essentially a treatise on why we should put away our phones and look around once in a while. So far it’s been an excellent read, very much in the vein of “How to See”, a fantastic photo book by George Nelson on identifying and cataloguing interesting themes in the world around you. In an attempt to put this into practice, I looked for something of interest on my motorcycle ride into work the other day. Though relatively banal, the first thing that caught my eye were the registration stickers on the cars around me. Just the day before I’d explained the process to my kids as we put a shiny new yellow 2020 sticker over the blue 2019 version on our car. As I rode in, I decided to conduct a quick experiment, counting the blues versus the yellows. This being July, I thought about 7/12 (~58%) of them would have already transitioned over to the 2020 version. I gave after I hit 50 yellows to 41 blues, which came out to 55% of the population….kind of a neat way to tell what month it is. Just by opening my eyes a little.

Volleyball Boss

ulm school

Just happened upon this old gallery of work from the Ulm school in Germany, long since closed, and founded by the great Otl Aicher & Max Bill. Would have been fascinating to sit in on a few of these classes.

http://www.ravenrow.org/galleries/the_ulm_model/

10m redesign: airstream nest

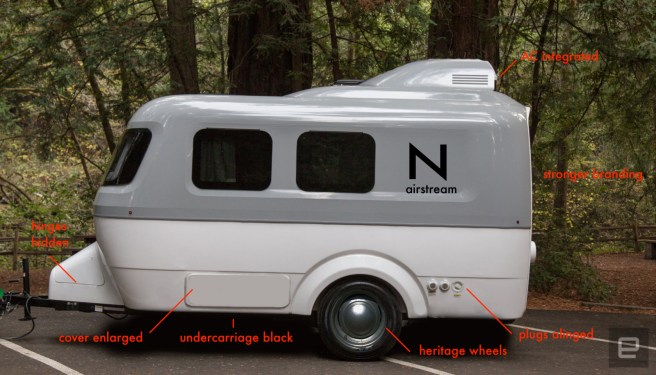

I read an interesting article on engadget about a futuristic airstream trailer which was a new direction for the company…more “minimalist” in their words. And here it is:

A couple of thoughts:

- If your company is lucky enough to have made one of the, say, top ten most iconic products in American history, maybe don’t change every single detail and lose any sense of heritage. I understand and endorse the need to innovate, and new materials are a critical part of that, but there’s not a single element that carries over from what I can tell.

- To call the above more minimalist than a traditional airstream seems pretty far off the mark. When one pictures the classic, it is essentially a riveted metal tube on wheels. The material and its manufacturing process make up the design–the “honesty” of the design is quintessential. For the nest, above, the fiberglass shell has been formed into a variety of soft & sharp edges. It might not have been effective, but it might have been interesting to see the material more (unpainted white fiberglass?) as with the classic.

- If you really have a clean slate design, how could one possibly end up with the mess of interconnect that you see along the bottom panel. Nothing corresponds with anything else. There are oblong reflectors next to circular ones. The labels are slapped on wherever convenient. I admittedly have no knowledge of the underlying constraints here, but it looks downright criminal to me.

With all that in mind, I took 10 minutes in photoshop to try to clean it up some. I’m still not in love with the wheel arch, but I ran out of time to fix that. The general idea was to clean up the mess, bring in a touch of heritage, and make it seem more cohesive (the AC appendage was especially galling). The branding change is more of a shot in the dark–I just think it should be bolder & say airstream on there. I know that this redesign would likely be more informed if I’d ever stayed in an camper trailer, but I’m still a tent guy. Anyhow, I would have loved to spend more time on this one and delve more into the overall form, but I think it was still an effective ten minutes.

Thanks to engadget for the image: https://www.engadget.com/2018/11/24/hands-on-airstream-nest/#/

small solutions

My daily commute consists of a short bike ride, then a bus ride, then another short bike ride to my office. It takes longer than I’d prefer but beats the fury of getting stuck in traffic and looking for parking spots. There are three different bike compartments under the bus and I used to check them at random hoping for a vacant spot. Some days I would get lucky on the first try, but on others I would have to check all three (and then sometimes go back to an earlier one if it was less full). This persisted for a full year, until I had a realization: if I always check the middle door, I can then look into both adjacent compartments before opening another door. Using this method I never have to open more than two doors. This is in no way an earth shattering revelation, but its eliminated a frustration and made me wonder how many other similar improvements I can make in my life. I don’t think I’m quite ready to go full turtleneck and new balance, but I will be keeping an eye out for small annoyances, and small solutions.

Prototyping

Some time ago I had this seemingly brilliant idea to design a vacuum top for my coffee bean containers, which I always purchased from Trader Joe’s. I already had a mechanical vacuum pump/stopper system for wine bottles, so it seemed like a natural fit to design a top that used the same pump. I could even see these tops getting sold at TJ’s along with the wine corks in a combo…who drinks wine and doesn’t like coffee? So excited, I kicked out a few graphic design concepts and starting going through some packaging ideas.

I figured I could work in a hexagon pattern into the mechanical structure and play off this bee keeper/bean keeper parallel. At the same time, I wired up an arduino and pressure sensor to measure the stability of the vacuum over time. Unfortunately I was always getting air leaks through the sensor cable bundle. I tried several sealing methods, but pressure loss was always relatively immediate and complete. No one was going to buy a vacuum top that didn’t keep vacuum. Eventually I realized that my sensor laden solution was overkill and added unnecessary failure modes. Instead, I just glued a wine stopper through a drilled hole in the metal canister bottom.

I figured I could work in a hexagon pattern into the mechanical structure and play off this bee keeper/bean keeper parallel. At the same time, I wired up an arduino and pressure sensor to measure the stability of the vacuum over time. Unfortunately I was always getting air leaks through the sensor cable bundle. I tried several sealing methods, but pressure loss was always relatively immediate and complete. No one was going to buy a vacuum top that didn’t keep vacuum. Eventually I realized that my sensor laden solution was overkill and added unnecessary failure modes. Instead, I just glued a wine stopper through a drilled hole in the metal canister bottom.

This thing leaked too…and then I realized that Trader Joes coffee containers aren’t airtight–essentially killing the whole idea. Could have saved myself plenty of time by doing a proof of concept first before all the other work. Good reminder to prototype relentlessly–sometimes the simpler the better.

Monograms

One of the enduring things about my Grandpa, who passed several years ago, were his many aphorisms. He remains probably the greatest character I have ever known, always cracking off about “keeping the car rubber side down”, or him “going to pour the water off the potatoes”. While those quotes run through my head frequently, I’m just as much reminded of him by seeing his custom monogram on the many things he left our family. He at some point had come up with a clever way to write his initials “E.D.” on seemingly every single thing he owned– apparently these leather shop gloves as well. It was his inspiration that lead me to create my own monogram some years ago, which I use to sign off on all of my work & journal entries. But this week I decided to take it a step further and have a stamp made (rubberstamps.com) to mark my shop tools and camera equipment. I used this stamp with some archival waterproof ink and tagged everything in my shop. It was probably the most satisfying afternoon I’ve had in quite a while. I’ll have to thank Gramps, until he’s better paid.

Painting Thoughts on Performance

I went out to Colorado last weekend to help my folks paint their house, something that sounded strange to my coworkers, and perhaps sounds strange to anyone who doesn’t know my family. Us Hendrens have long had something of a moral imperative to produce almost incessantly–something I figured was a kind of midwest work ethic on steroids. Oddly enough, on the flight out I happened to be reading “Meditations” by Marcus Aurelius and one of his admonitions from the first book was “moreover, to endure labour, nor to need many things; when I have anything to do, to do it myself rather than by others…” So I guess it didn’t start in Minnesota, although we are also Italian.

For anyone who has spent a fair amount of time painting, or really performing manual labor of any type, you know that one enters into a state where the body becomes autonomous and the mind is freed to wander without tending to the physical. In my 48 hours there, I had a sort of ongoing dialogue about the metrics of performance. For instance, I painted houses through my high school summers so I knew we were doing a professional-level job as far as quality was concerned. It’s just that real pro’s might have done it 5% quicker. Or perhaps they would have done it 3% better (or XX% worse, as I’ve often seen with professionals for whom time literally equates to money).

That got me thinking about the professions with the smallest of margins: think race car drivers or downhill skiers. For those people, milliseconds separate victory from defeat. I wonder in those cases if natural talent more often accounts for the difference, or perhaps it is duration/intensity of training. Though most likely it is a combination of both with a strong dose of luck, something too infrequently mentioned in our assumed meritocracy. Anyhow, we got the job done, and it was back on the plane. I knew I hadn’t come to any real conclusions in any of my meandering, but they were interesting things to ponder, to perhaps pursue more later. Marcus had one more thing to say on the matter, “The happiness of your life depends upon the quality of your thoughts.”

Baker Hardwoods

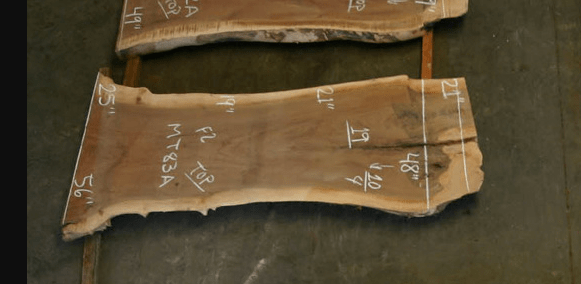

I’d been wanting to build a live edge walnut coffee table for some time, since it seemed like a nice juxtaposition to our relatively modern house motif…plus, who doesn’t love having another project to work on. Scouring for local sources I found an intriguing one not too far from our home in Santa Cruz: Baker Hardwoods in Gilroy. Spending a fair amount of time on their site, I eventually came across what looked like a good deal on the right size piece: MT83A. I called to make sure it was still available, and then had them set it aside for me.

The next morning we actually had a work offsite at the nearby Coyote Valley Sporting Clays, so I figured I would stop by and pick up the slab then head over to meet the group for shooting. Five minutes after meeting Jim Baker, I called my coworkers to say I wasn’t going to make it–instead spending two and half hours learning from one of the most interesting men I’ve ever met.

When you show up at Baker Hardwoods you encounter a big steel gate with a huge red circle in the center–something that wouldn’t make sense until later. I called again, and they opened the gate as I drove around back to the mill. There I met Jim Baker, who was busy loading some material into a kiln on a vintage Toyota Forklift. I asked how he was doing, and he said, “I’m 80.”

We set about looking for the piece, which took us through the many store rooms and drying facilities. As we walked I became more and more fascinated by Jim’s history. He’d spent over 10 years in university, earning five degrees from fields of biology to psychology. “Too much desk time”, he said, “too fucking boring.” He nonchalantly mentioned that he spent several years in Japan training for the 1964 Olympics, amidst his many other adventures abroad. He returned to the states with a wife and took up the family business of milling, while retaining an appreciation for traditional Japanese craftsmanship. My final project at Apple had taken me to Japan many times, where I had likewise learned to appreciate the methodical work and attention to detail with which the Japanese are renowned. We chatted on effortlessly as I tried to absorb as much as I could from the man’s experience.

We finally located the piece in the back corner of the yard, and he offered to help me clean it up (generally an additional charge). The piece I had chosen was harvested from a black walnut grove in Gilroy; it had been drying at his facility for years. The first step was to check the slab for metal with a metal detector (to protect against damage to the cutting or planing blades). Then we created some clean end cuts, while I surreptitiously tried to snap a shot–a bit embarrassed for my document-before-experience generation. I think he saw me in the corner of his eye, which probably accounts for the frown.

After checking the flatness of the board there was a slight warp up to one corner, so he offered to plane it. We ran it through two times on each side, and the it revealed some nice figuring and also the graft mark were a piece of english walnut had been grafted onto a claro walnut (black walnut) trunk. There’s a neat religious analogy for those who know Judeo-Christian history. After we planed the board, he had a take a quick call, and I heard him swing into fluent a Japanese “moshi moshi” as he rounded the corner. He was back several minutes later and we discussed finishing options.

The board had some end cracking, and he suggested filling it with two part epoxy mixed with graphite powder (I would go on to make my own from worn down carpenter pencil stubs, in a nod to the concept of “Mottainai”, worth a whole other post). Before I left he said he wanted to show me one of his pet projects: a majestic ten by four foot slab he was building for his wife as she struggled through an illness. The craftsmanship was impeccable, and I got to see the proper way to brace against a slab’s warpage power with steel c-channel. I told him I wished I could have spent the full day, and he invited me to come back at will.

My project finished up several days later and turned out pretty well for my first fine furniture attempt. For the base I used the cut-offs from some steel shelves in my garage (more mottainai!), though I’d be embarrassed if anyone looked too closely at the welds. The crack filled well with the graphite epoxy, and everything came together well.

Stapled in the middle of the bottom is the original tag from the collection date. I hope Jim Baker would approve.

What is Design?

great summary of design definition from Eames

1972

The questions and answers below were the conceptual basis of the exhibition Qu’est ce que le design? (What is Design?) at the Musée des Arts Décoratifs, Palais de Louvre in 1972.

Questions by Madame. L. Amic, answers by Charles and Ray Eames:

Q: “What is your definition of ‘Design,’ Monsieur Eames?

A: “One could describe Design as a plan for arranging elements to accomplish a particular purpose.”

Q: “Is Design an expression of art?”

A: “I would rather say it’s an expression of purpose. It may, if it is good enough, later be judged as art.”

Q: “Is Design a craft for industrial purposes?”

A: “No, but Design may be a solution to some industrial problems.”

Q: “What are the boundaries of Design?”

A: “What are the boundaries of problems?”