I’d been wanting to build a live edge walnut coffee table for some time, since it seemed like a nice juxtaposition to our relatively modern house motif…plus, who doesn’t love having another project to work on. Scouring for local sources I found an intriguing one not too far from our home in Santa Cruz: Baker Hardwoods in Gilroy. Spending a fair amount of time on their site, I eventually came across what looked like a good deal on the right size piece: MT83A. I called to make sure it was still available, and then had them set it aside for me.

The next morning we actually had a work offsite at the nearby Coyote Valley Sporting Clays, so I figured I would stop by and pick up the slab then head over to meet the group for shooting. Five minutes after meeting Jim Baker, I called my coworkers to say I wasn’t going to make it–instead spending two and half hours learning from one of the most interesting men I’ve ever met.

When you show up at Baker Hardwoods you encounter a big steel gate with a huge red circle in the center–something that wouldn’t make sense until later. I called again, and they opened the gate as I drove around back to the mill. There I met Jim Baker, who was busy loading some material into a kiln on a vintage Toyota Forklift. I asked how he was doing, and he said, “I’m 80.”

We set about looking for the piece, which took us through the many store rooms and drying facilities. As we walked I became more and more fascinated by Jim’s history. He’d spent over 10 years in university, earning five degrees from fields of biology to psychology. “Too much desk time”, he said, “too fucking boring.” He nonchalantly mentioned that he spent several years in Japan training for the 1964 Olympics, amidst his many other adventures abroad. He returned to the states with a wife and took up the family business of milling, while retaining an appreciation for traditional Japanese craftsmanship. My final project at Apple had taken me to Japan many times, where I had likewise learned to appreciate the methodical work and attention to detail with which the Japanese are renowned. We chatted on effortlessly as I tried to absorb as much as I could from the man’s experience.

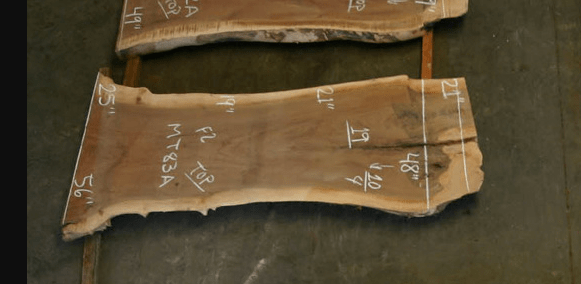

We finally located the piece in the back corner of the yard, and he offered to help me clean it up (generally an additional charge). The piece I had chosen was harvested from a black walnut grove in Gilroy; it had been drying at his facility for years. The first step was to check the slab for metal with a metal detector (to protect against damage to the cutting or planing blades). Then we created some clean end cuts, while I surreptitiously tried to snap a shot–a bit embarrassed for my document-before-experience generation. I think he saw me in the corner of his eye, which probably accounts for the frown.

After checking the flatness of the board there was a slight warp up to one corner, so he offered to plane it. We ran it through two times on each side, and the it revealed some nice figuring and also the graft mark were a piece of english walnut had been grafted onto a claro walnut (black walnut) trunk. There’s a neat religious analogy for those who know Judeo-Christian history. After we planed the board, he had a take a quick call, and I heard him swing into fluent a Japanese “moshi moshi” as he rounded the corner. He was back several minutes later and we discussed finishing options.

The board had some end cracking, and he suggested filling it with two part epoxy mixed with graphite powder (I would go on to make my own from worn down carpenter pencil stubs, in a nod to the concept of “Mottainai”, worth a whole other post). Before I left he said he wanted to show me one of his pet projects: a majestic ten by four foot slab he was building for his wife as she struggled through an illness. The craftsmanship was impeccable, and I got to see the proper way to brace against a slab’s warpage power with steel c-channel. I told him I wished I could have spent the full day, and he invited me to come back at will.

My project finished up several days later and turned out pretty well for my first fine furniture attempt. For the base I used the cut-offs from some steel shelves in my garage (more mottainai!), though I’d be embarrassed if anyone looked too closely at the welds. The crack filled well with the graphite epoxy, and everything came together well.

Stapled in the middle of the bottom is the original tag from the collection date. I hope Jim Baker would approve.

In May undertook a project in a similar vein — I refinished a piece of live edge eastern black walnut that was sitting in my parent’s attic for the last 20 years into a coffee table. I think what I appreciate the most about the resulting product is in it’s imperfections, each of which adds to it’s character.

Almost always in engineering at scale, we strive to remove sources of variation or defects to improve yield and consistency. This is understandable, but I think there is something deeply satisfying in taking on a personal project that embraces these defects and even highlights them as a part of the overall product. A product that -while flawed- holds a book or a cup of coffee just as well as the latest from IKEA, and does so with much more personality.

Yours looks great! Here’s mine:

My first foray into hardwoods sparked a serious interest in woodworking for me – my next undertaking is to create a bed in a similar style to the Nelson thin edge bed.

Ha, sorry for the delay Brad–I didn’t even know people could leave comments here. Your table looks awesome–I like the pin leg look and just put some of those on another project. Agree on your comments about how mass production has tended to neglect the character of materials. I struggled with the need to remove all of inconsistencies from the face until my wife just said…”it’s a piece of wood, just leave it alone.” easier said than done…look forward to seeing how your next project turns out.